Successful pilot plant for waste water recycling in pulp and paper production

Water scarcity and driving sustainability are the reasons why many producers of paper and board are reducing their water footprint through innovative wastewater recycling.

One example is another successful and recent pilot project together with a leading Scandinavian pulp & paper group: GAW showed that the waste water recycling perfectly meets the expectations in terms of technical and economic feasibility.

Project Overview:

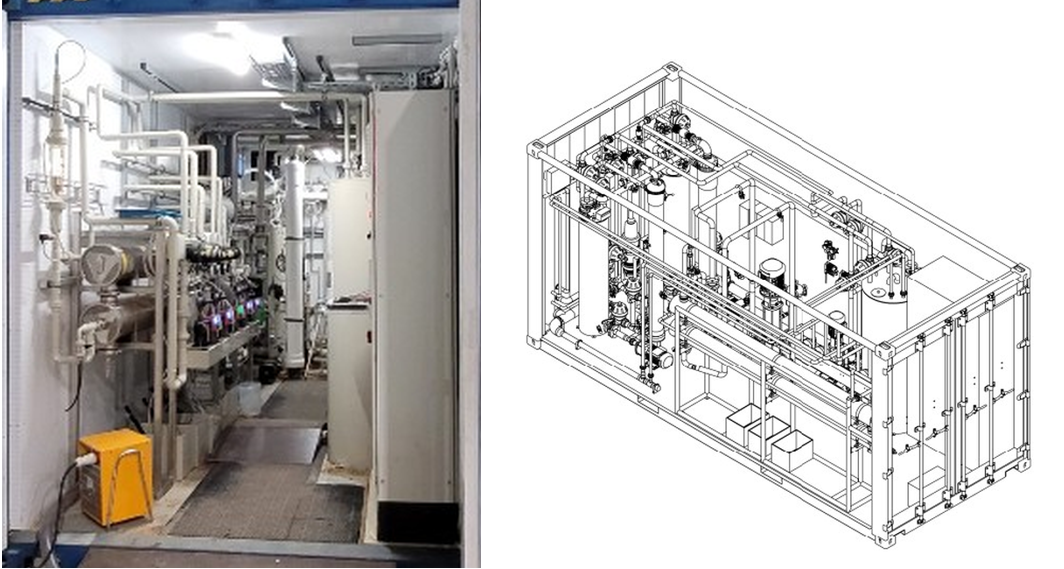

To explore this potential, GAW water technologies deployed a state-of-the-art, containerized pilot plant equipped with an Integrated Membrane System (Ultrafiltration + Reverse Osmosis) supplied by the sister company Osmo Membrane Systems. The plant treated secondary effluent from their existing biological treatment process, with the goal of producing recycled water that meets or exceeds the quality of their current process water.

Challenges & Solutions:

The wastewater from pulp & paper mills can be tough to treat, even after biological processing, due to high COD, hardness, and colloidal matter. But the membrane solution from GAW technologies GmbH delivered:

✅ Very reliable treatment with zero incidents

✅ Low pressure operation throughout the 4-week pilot

✅ Recycled water quality far surpassing the targets

Key Outcomes & Impact:

✔️ Water footprint reduction potential of 30-50%

✔️ Significant energy savings by reusing warm effluent water

✔️ Lower wastewater discharge and reduced dependency on fresh water

✔️ Enhanced operational security and sustainability in production

These results allowed us to estimate operating and investment costs for a potential large-scale recycling plant, and we can report that both fall within economically viable boundaries.

This pilot marks a significant step forward in optimizing the water footprint in pulp and paper production. 🌿 It proofs that innovative solutions can create lasting environmental impact while supporting operational goals!

November 2024